In this article, you will learn more about hydraulic pumps, their operation, and the different types available in the market.

Table of Contents

What is a hydraulic pump?

A hydraulic pump is a mechanical component that converts mechanical energy into hydraulic energy. It is the hydraulic component responsible for generating flow with enough power to overcome pressure induced by a load in the hydraulic system. The flow generated by the hydraulic pump determines the speed of movement of the system's actuators.

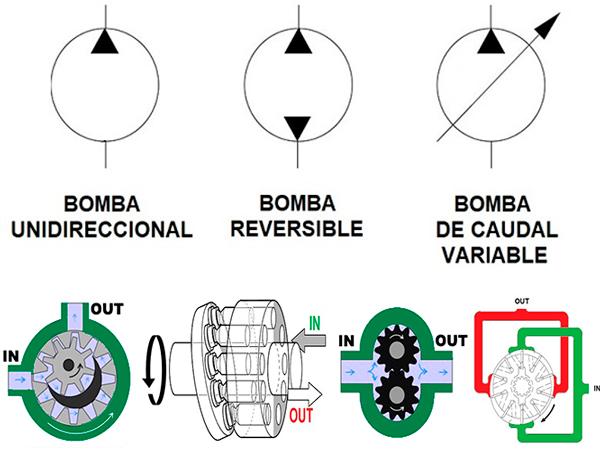

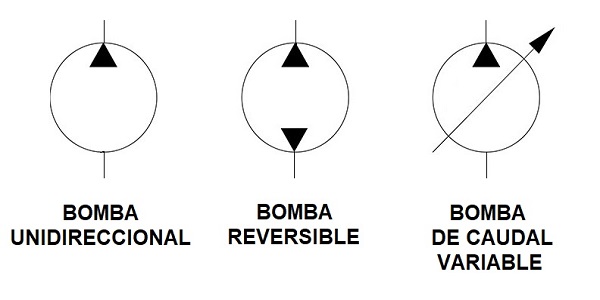

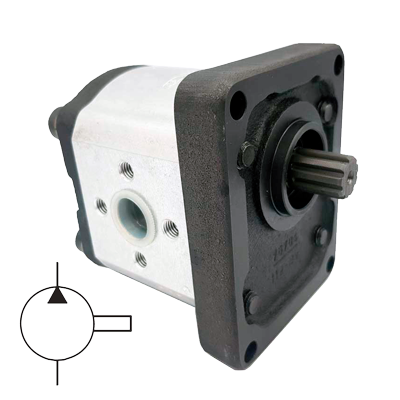

Symbol of the hydraulic pump in hydraulic circuits.

What is a hydraulic pump used for?

It could be said that it is the heart of our hydraulic circuit. It is the component responsible for generating flow (hydraulic energy) from a mechanical energy source. This mechanical energy source can be an electric, pneumatic, hydraulic motor, manual effort, etc.

Operation of the hydraulic pump.

When a hydraulic pump is working, a vacuum pressure is generated at the pump's inlet, creating a pressure differential with respect to atmospheric pressure. This effect causes the liquid from the reservoir to move towards the pump's inlet.

Once the liquid from the reservoir is "sucked" by the pump, it, through its mechanical action, sends the liquid to the pump's outlet and forces its movement into the hydraulic circuit.

IMPORTANT!

A hydraulic pump generates flow of liquid but does not generate pressure. Pressure is generated in the hydraulic system based on the resistance offered by the components of the circuit to the flow of the liquid displaced by the pump.

That is, if the pump's outlet is not connected to any load, the pressure will be equal to 0 (or practically negligible), and if the outlet is connected to one or more loads, the pressure will increase to a sufficient value to overcome the resistance caused by these loads.

Types of hydraulic pumps.

Pumps can be classified into positive displacement pumps (also called hydrostatic pumps) and non-positive displacement pumps (hydrodynamic pumps).

The pumps used in hydraulic systems are mostly positive displacement hydraulic pumps and are characterized, unlike non-positive displacement pumps, by having very low slippage or slip when pressure increases compared to volumetric flow.

Slippage in positive displacement pumps refers to the losses that may occur in the volumetric output of the pump or can also be defined as internal flow losses from the pump outlet to the inlet.

The slippage in positive displacement pumps is very low due to the very tight manufacturing tolerances between the moving parts and the body containing them.

Positive displacement pumps deliver the same amount of fluid in each cycle, regardless of the speed at which the pump's moving parts rotate (rotary) or displace (reciprocating or alternating). Therefore, the faster the moving parts of the hydrostatic pump move, the higher the hydraulic flow will be.

As mentioned earlier, in positive displacement hydraulic pumps (hydrostatic), there are basically two types: reciprocating (or alternating) and rotary.

In this article, we will focus on positive displacement rotary hydraulic pumps.

Types of rotary hydraulic pumps.

In this type of pumps, the fluid moves from the inlet to the outlet through a rotary motion, and depending on the type of moving element that displaces the fluid, rotary hydrostatic hydraulic pumps are classified as:

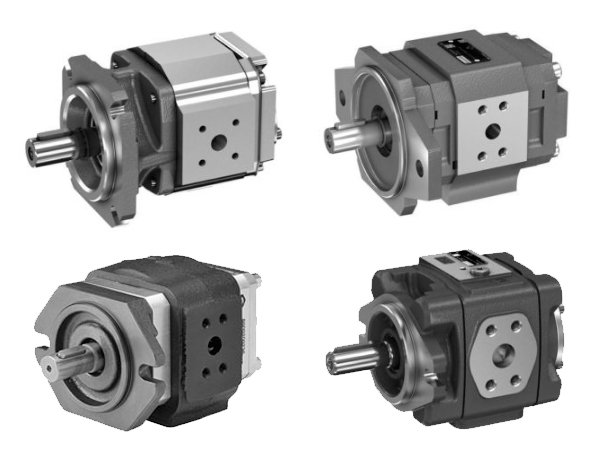

External gear hydraulic pumps.

The design of external gear hydraulic pumps consists of two identical straight (or helical) gears that rotate interconnected within a body.

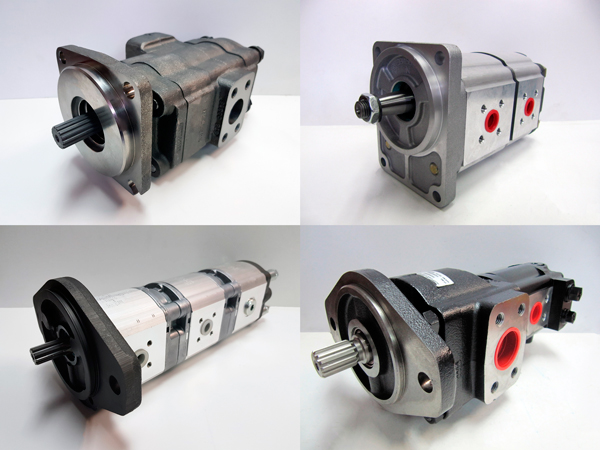

Also known as pinion pumps or gear pumps. Due to their compact design, robustness, and economical price, gear pumps are a very common choice in all types of hydraulic machinery and in all market sectors.

The number of options within this type of pumps is very extensive:

- - Gear pumps with aluminum or steel bodies (cast).

- - Gear pumps with single or multiple bodies.

- - Unidirectional hydraulic pumps (clockwise or counterclockwise rotation) or reversible pumps (both with internal and external drainage) that can rotate in both directions.

- - Various types of shafts (tapered, splined, cylindrical, etc.).

- - A wide variety of front flanges: European type (also called Italian flange), SAE type, Bosch type, etc.

- - All kinds of pump inlet/outlet ports: BSP threaded ports (GAS), UNF-SAE thread, SAE-type flange, etc.

- - Depending on the compatibility of the hydraulic fluid to be used in the system or the maximum/minimum working temperature, the gear hydraulic pump can also be configured according to the type of material in internal seals and shaft seal: NBR, FKM, Viton, etc.

- - Valves integrated into the pump itself: the pump can be configured with or without an integrated pressure relief valve, with an anti-cavitation valve, with an LS Load Sensing valve, with an electric bypass valve, with a flow control valve, etc.

External Gear Hydraulic Pumps with Aluminum Body

Depending on the manufacturer, these pumps can be categorized into different groups based on size and displacement:

- Group 0.

- Group 1.

- Group 2.

- Group 3.

- Group 3,5.

- Group 4.

External Gear Hydraulic Pumps with Cast Iron Body

They are used in situations where aluminum pumps are pushed to their design limits due to the type of application, the duty cycle, or the demanding pressure conditions during the cycle.

Like aluminum pumps, cast iron body pumps are available in a multitude of configurations and sizes based on their displacement, drive shaft type, mountings and ports, integrated valves, double and triple hydraulic pumps, etc.

Manual hydraulic pumps.

The design of these pumps consists of a piston or plunger driven by a handle or lever that moves the piston inside a cylinder to displace the hydraulic fluid.

They are used in applications where there is no power source to operate an automatic pump or where the hydraulic fluid must be pumped manually to perform maintenance or other manual operations.

Internal gear hydraulic pumps.

The design of internal gear hydraulic pumps consists of two gears with different numbers of teeth that rotate together.

Internal gear pumps have low noise levels and are known for their efficiency and performance. They are commonly used in applications where noise is a concern, such as in mobile equipment and industrial machinery.

Vane hydraulic pumps.

The design of vane hydraulic pumps consists of a rotor with slots in which vanes are placed.

Vane pumps are known for their simplicity, reliability, and self-priming capabilities. They are commonly used in applications where a steady flow of hydraulic fluid is required, such as in automotive power steering systems and industrial machinery.

Piston hydraulic pumps.

The design of piston hydraulic pumps consists of one or more pistons that move back and forth inside cylinders to displace the hydraulic fluid.

Piston pumps are known for their high efficiency and pressure capabilities. They are commonly used in applications where high pressure and precise control of hydraulic flow are required, such as in construction equipment and manufacturing machinery.

Each type of rotary hydraulic pump has its own advantages and limitations, making them suitable for different applications. It is essential to choose the right type of hydraulic pump for your specific hydraulic system requirements to ensure optimal performance and efficiency.

If you have any questions or need assistance in selecting the appropriate hydraulic pump for your application, please feel free to contact us.

We hope you found this article informative and helpful in understanding the different types of rotary hydraulic pumps available in the market and their applications.

If you would like to learn more about our hydraulic pump products and services, please visit our hydraulic pumps page or contact us directly. We would be happy to assist you with your hydraulic pump needs.

At Hidraoil Fluid Power, we are committed to providing high-quality hydraulic components and excellent customer service to meet your hydraulic system requirements. Thank you for reading!

Create Date: 2024-01-14 18:00:00

Update date: 2024-08-21 09:00:00

SHIPPING WORLDWIDE

Let us assist you in choosing the perfect hydraulic component for your machine or upcoming project. We offer expedited shipping to anywhere in the world through top logistics companies such as DHL Express, TNT, FedEx or UPS.